Food Vacuum Sealer

Food Vacuum Sealer Products List

What Are the Advantages of a Vacuum Sealer?

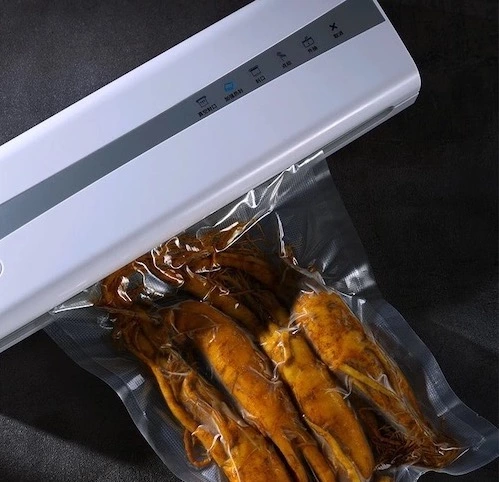

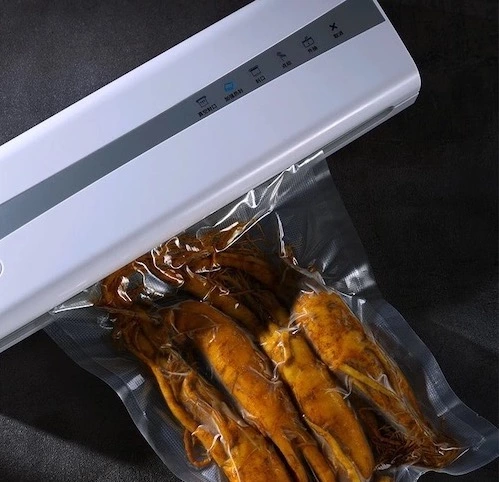

One of the main benefits of a vacuum sealer is that it extends the shelf life of food by preventing spoilage caused by exposure to air and moisture. This makes it an ideal tool for preserving perishable items such as meat, fish, fruits, and vegetables. Another advantage of using a vacuum sealer is that it helps save money by reducing food waste. By sealing leftovers or bulk purchases, you can prevent them from going bad and throwing them away. Additionally, vacuum-sealed food takes up less space in the refrigerator or freezer, allowing you to store more items. Vacuum sealers are also great for sous vide cooking as they create an airtight seal around the food which helps retain its natural flavor and nutrients during cooking. Overall, investing in a vacuum sealer can be beneficial for anyone who wants to save money on groceries while keeping their food fresh for a longer time.

Applications of A Vacuum Sealer

The applications of a vacuum sealer are numerous, making it an essential tool in many industries and households. In the food industry, vacuum sealers are used to preserve food by removing air and preventing the growth of bacteria. This extends the shelf life of food products, reduces waste, and saves money. In households, vacuum sealers are popular for preserving leftovers or bulk purchases of meat or produce. They can also be used to protect important documents or keepsakes from moisture and dust. Vacuum sealers are also commonly used for packing delicate items such as electronics or medical equipment. By removing air from the packaging, these items are protected from damage during shipping or storage. A vacuum sealer is used for food that is dry, crispy, soft and contains oil.

Features of Vacuum Sealers

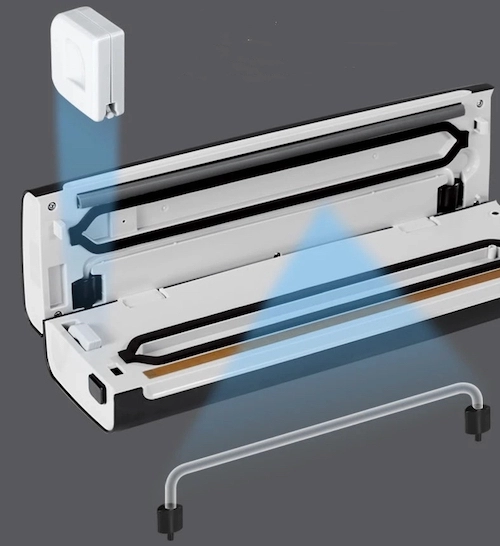

One of the most important features of a vacuum sealer is its ability to remove air from the packaging. This helps to prevent the growth of bacteria, which can cause food spoilage. Another important feature is its sealing mechanism, which creates an airtight seal around the food. Vacuum sealers also come with different settings that allow users to adjust the level of suction and sealing time according to their specific needs. Some models even come with built-in bag cutters and roll storage compartments, making it easier for users to customize their bags. A vacuum sealer has small sizes and it is easy to operate and store, which is great for households.

Extended sealing length

Efficient multi-package continuous sealing

Supporting multiple packages

Simultaneous sealing operation

Sealing small bags

Various texture bags

Reinforced sealing

Vacuum sealing

Pleasant operating experience

Energy saving

Multiple modes

Good suction

Overheating protection

Touch sensor

Functions

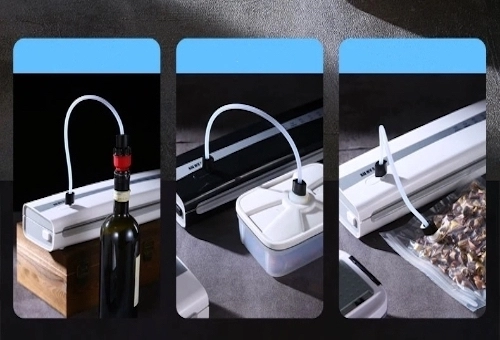

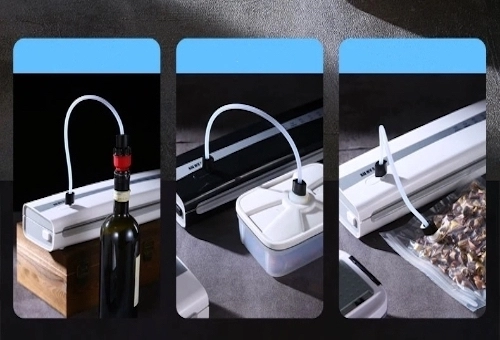

External suction

The vacuum sealer is equipped with an external suction tube, which can be used with vacuum tanks, wine bottle stoppers, suction nozzle Ziplock bags for vacuuming, and has a wider range of uses.

Self-adjusting vacuum strength

Vacuum strength can be manually controlled, which is specially designed for fragile and deformable food.

Vacuum sealing

Multi-package and continuous working are available. Multi bags can be vacuum sealed at the same time, which improves efficiency.

Strengthened heat sealing

Increase the sealing time and temperature to enhance the sealing effect. For thicker bags or bags with juices, the vacuum sealer does the job perfectly.

Quick sealing

The whole process of sealing is simple and quick. Vacuum bags with various textures, corner bags, ordinary flat bags within 30cm can be sealed.

One of the main benefits of a vacuum sealer is that it extends the shelf life of food by preventing spoilage caused by exposure to air and moisture. This makes it an ideal tool for preserving perishable items such as meat, fish, fruits, and vegetables. Another advantage of using a vacuum sealer is that it helps save money by reducing food waste. By sealing leftovers or bulk purchases, you can prevent them from going bad and throwing them away. Additionally, vacuum-sealed food takes up less space in the refrigerator or freezer, allowing you to store more items. Vacuum sealers are also great for sous vide cooking as they create an airtight seal around the food which helps retain its natural flavor and nutrients during cooking. Overall, investing in a vacuum sealer can be beneficial for anyone who wants to save money on groceries while keeping their food fresh for a longer time.

Applications of A Vacuum Sealer

The applications of a vacuum sealer are numerous, making it an essential tool in many industries and households. In the food industry, vacuum sealers are used to preserve food by removing air and preventing the growth of bacteria. This extends the shelf life of food products, reduces waste, and saves money. In households, vacuum sealers are popular for preserving leftovers or bulk purchases of meat or produce. They can also be used to protect important documents or keepsakes from moisture and dust. Vacuum sealers are also commonly used for packing delicate items such as electronics or medical equipment. By removing air from the packaging, these items are protected from damage during shipping or storage. A vacuum sealer is used for food that is dry, crispy, soft and contains oil.

Features of Vacuum Sealers

One of the most important features of a vacuum sealer is its ability to remove air from the packaging. This helps to prevent the growth of bacteria, which can cause food spoilage. Another important feature is its sealing mechanism, which creates an airtight seal around the food. Vacuum sealers also come with different settings that allow users to adjust the level of suction and sealing time according to their specific needs. Some models even come with built-in bag cutters and roll storage compartments, making it easier for users to customize their bags. A vacuum sealer has small sizes and it is easy to operate and store, which is great for households.

Extended sealing length

Efficient multi-package continuous sealing

Supporting multiple packages

Simultaneous sealing operation

Sealing small bags

Various texture bags

Reinforced sealing

Vacuum sealing

Pleasant operating experience

Energy saving

Multiple modes

Good suction

Overheating protection

Touch sensor

Functions

External suction

The vacuum sealer is equipped with an external suction tube, which can be used with vacuum tanks, wine bottle stoppers, suction nozzle Ziplock bags for vacuuming, and has a wider range of uses.

Self-adjusting vacuum strength

Vacuum strength can be manually controlled, which is specially designed for fragile and deformable food.

Vacuum sealing

Multi-package and continuous working are available. Multi bags can be vacuum sealed at the same time, which improves efficiency.

Strengthened heat sealing

Increase the sealing time and temperature to enhance the sealing effect. For thicker bags or bags with juices, the vacuum sealer does the job perfectly.

Quick sealing

The whole process of sealing is simple and quick. Vacuum bags with various textures, corner bags, ordinary flat bags within 30cm can be sealed.

Classifications of a Vacuum Sealer

There are different classifications of household vacuum sealers based on their features and functions. The first classification is the handheld vacuum sealer, which is small and portable. It is ideal for sealing small packages such as snacks, fruits, and vegetables. The second classification is the countertop vacuum sealer, which is larger and more powerful than the handheld version. It can seal larger packages such as meat, fish, and poultry. The third classification is the chamber vacuum sealer, which has a chamber where the package is placed for sealing. This type of vacuum sealer can handle large volumes of food items at once. Lastly, there are specialty vacuum sealers that have additional features such as automatic bag detection, adjustable sealing time, and built-in cutters for custom-sized bags.

Some models use heat to seal bags, while others use a clamp or clip to secure the bag before removing air. Heat-sealing models are faster but may not be suitable for delicate foods like fruits and vegetables. Lastly, some handheld vacuum sealers come with additional features like adjustable suction strength, reusable bags, and compatibility with different types of containers.

Vacuum sealing VS normal storage

Freshness

Vacuum sealing can keep the original taste and nutrition.

Oxygen removal

Prevent food from spoiling.

Moisture-proof

Vacuum can prevent moisture and mildew.

Health

Prevent germs from multiplying.

Keep moisture and the food is fresh as if it is just picked from the farm.

The taste is good, and the food is as fresh as it was just bought.

Tips for Sealing Vegetables

Blanching is a necessary process before vacuum sealing vegetables. This process stops the action of enzymes, which can lead to loss of flavor, color and texture. Vegetables can be blanched in boiling water or the microwave and still be crisp. Blanching times can range from 1 to 2 minutes for potherb and peas; 3 to 4 minutes for sliced peas, zucchini, or broccoli, 5 minutes for carrots, and 7 to 11 minutes for corn on the cob. After blanching, soak the vegetables in cold water to stop the cooking process.

All vegetables including broccoli, brussels sprouts, cabbage, cauliflower, kale, spinach and radishes naturally emit gas during storage. Therefore, after blanching, it's best to keep them in the fridge. When storing vegetables, pre-freeze them for 1 to 2 hours and put them into a vacuum bag. Once they are vacuum-sealed, place them in the refrigerator.

Fresh mushrooms, onions and garlic should never be vacuum packed due to the risk of anaerobic bacteria.

Tips for Sealing Powder

When vacuum packaging powdery items such as flour, it is best to pack the powder in the original package or an inner bag; fold the opening, and then put it into a vacuum bag for vacuum packaging; to avoid fine powder getting into the sealer, causing damage and shortening its service life.

Tips for Sealing Liquids

Before you vacuum pack liquids such as soup, it can be pre-frozen in containers until it is solid. Take the frozen liquid out of the container and vacuum seal it in a vacuum bag. You can then refrigerate it in the refrigerator. When you need to use it, just cut off a corner of the bag and put it in the microwave or simmer it on low heat below 170°F (75°C).

Parts of Vacuum Sealers

There are several parts of a household vacuum sealer that work together to preserve food for longer periods.

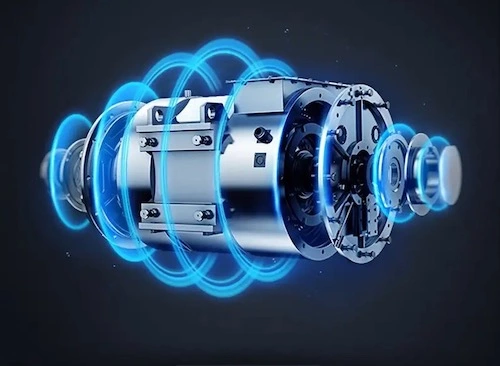

Vacuum Pump

The first part is the vacuum pump, which creates suction and removes air from the packaging.

Features of Vacuum Pumps

Fast driven vacuum pumps with next-generation technology

Powerful inner core, energy saving and noise reduction

High speed

Good suction

Silent pump

Smart core

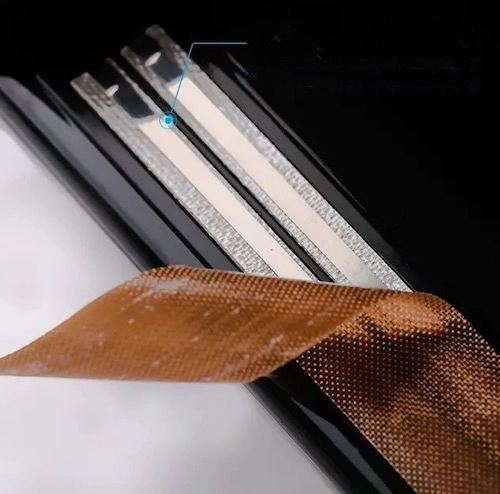

Sealing Bar

The second part is the sealing bar, which seals the bag after the air has been removed. The sealing bar can be either heated or have a mechanical locking mechanism.

Sealing Tape

A seal tape is a thin strip of adhesive material that is used to seal the bags or containers that hold food items. The tape works by creating an airtight seal between the bag and the vacuum sealer, preventing air from entering or escaping. The sealing tape is made of high-quality materials that are durable and long-lasting. It can withstand high temperatures and pressure, ensuring that the food remains fresh for longer periods.

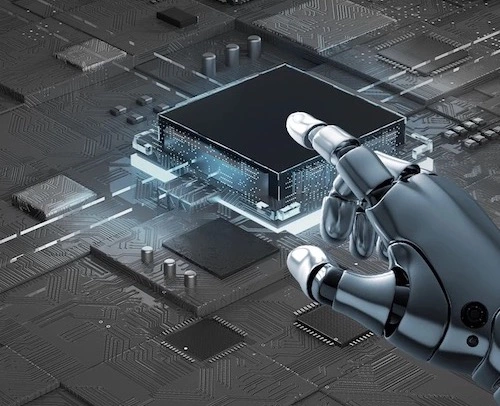

Circuit Board

The circuit board of a household vacuum sealer is a crucial component that enables the device to function effectively. It is responsible for controlling the various functions of the vacuum sealer, including sealing and vacuuming. The circuit board comprises several electronic components, including resistors, capacitors, diodes, and transistors. These components work together to regulate the voltage and current flowing through the device's circuits. The circuit board also contains a microcontroller that acts as the brain of the vacuum sealer. The microcontroller receives input from various sensors in the device and uses this information to control its operations. In addition to controlling the sealing and vacuuming functions, the circuit board also ensures safety by monitoring temperature levels and preventing overheating. Overall, without a properly functioning circuit board, a household vacuum sealer would not be able to perform its intended functions. Therefore, it is essential to ensure that this component is well-maintained and regularly checked for any faults or malfunctions.

Heating Element

A heating element is responsible for sealing the bags that hold the food to be stored. The heating element works by melting the plastic bag and fusing it to create an airtight seal. It is made from a high-quality metal alloy that can withstand high temperatures without degrading or breaking down. It is designed to heat up quickly and maintain its temperature throughout the sealing process. The efficiency and effectiveness of the heating element are critical in ensuring that food is properly sealed and preserved. A poorly functioning heating element can result in air leaks, which can cause spoilage and contamination of food.

Removable Vacuum Slot

The removable vacuum slot is responsible for creating a vacuum seal on the food bag, which ensures that air and moisture are removed from the bag, thereby preventing spoilage. The removable vacuum slot is designed to be easily detachable from the main unit, making it easy to clean and maintain. It can be washed with soap and water or placed in a dishwasher for thorough cleaning. Furthermore, this component plays a crucial role in ensuring that the vacuum sealer operates efficiently. If it becomes clogged with debris or food particles, it can affect the performance of the appliance and lead to suboptimal results.

Bag Roll Holder

Another important part of a household vacuum sealer is the bag roll holder, which holds the bag roll in place while it's being sealed.

Built-in Cutter

Some models also come with a built-in cutter that allows you to cut bags to your desired length.

Control Panel

There is a control panel, which allows you to adjust settings such as seal time and vacuum strength. There are drawings and characters on the control panel, which is convenient for people of all ages to operate. The whole process from removing air to sealing is simple and quick.

Indication Lights

Indication lights provide valuable information to the user about the status of the machine and its operation. The most common indication lights found on a vacuum sealer are power, seal, and vacuum. The power light indicates that the machine is plugged in and ready to use. The seal light indicates that the sealing process is in progress, while the vacuum light indicates that the vacuuming process is underway. These lights help users to understand what stage of operation their machine is at and when it's safe to open or close it. Moreover, indication lights also serve as a warning system for potential problems with the machine. If a malfunction occurs during operation, such as overheating or a clogged airway, an indicator light will alert users to stop using it immediately.

Smart chips

With the addition of smart chips, it can also be used normally in high-altitude areas.

Other parts

The structure of aluminum strip heat sink is adopted, which can be vacuumed and sealed 200 times without overheating, and the efficiency is greatly improved. High-temperature-resistant Teflon tape is selected. Aluminum strips can dissipate heat and quickly cool down the vacuum sealer. Insulation boards and nickel alloy heating wires are adopted.

What Is a Vacuum Sealer Made From?

The materials used to make a vacuum sealer vary depending on the manufacturer and model. The body of a vacuum sealer is typically made from ABS or stainless steel, with some models featuring stainless steel exteriors for durability and aesthetics. The interior components are often made from plastic or rubber materials that are resistant to corrosion and wear. Overall, the materials used to make a vacuum sealer are chosen for their durability, corrosion resistance, and ability to withstand repeated use over time.

How to Manufacture Vacuum Sealers?

Manufacturing vacuum sealers require a careful process that involves several steps. The first step in manufacturing vacuum sealers is designing the product. This includes deciding on the size, shape, and features of the sealer.

Design: The first step is to design the vacuum sealer, including the type of vacuum pump, the size of the sealer, the material used for the housing, and the controls for the vacuum and sealing processes.

Manufacturing: Once the design is finalized, the manufacturer will begin production by sourcing materials such as plastic, metal components, and electronics. The plastic parts are typically injection-molded while metal components are fabricated using various techniques such as stamping or machining. The electronics used in vacuum sealers include motors, heating elements, and control circuits.

Assembly: The next step is to assemble the components into the vacuum sealer. This will involve fitting the pump and heating element into the housing, connecting the wiring and controls, and attaching the sealing strip.

Testing: After assembly, the vacuum sealer will need to be tested to ensure that it functions properly. This will involve vacuum sealing various types of products to ensure that the vacuum pump generates sufficient vacuum and the sealing strip seals the bag properly.

Quality Control: Once the vacuum sealer has been tested and is functioning correctly, you will need to implement quality control measures to ensure that each product meets the required standards.

Packaging: Finally, the vacuum sealers will need to be packaged and directly sent to customers.

Maintenance of a Vacuum Sealer

The first step in maintaining a vacuum sealer is to clean it after every use. This involves wiping down the exterior with a damp cloth and cleaning the sealing strip with a soft brush. Another important aspect of maintenance is replacing the sealing strip when it starts to show signs of wear and tear. This will ensure that the vacuum sealer continues to work effectively and prevent any leaks during the sealing process. It is also important to check the suction power of the vacuum sealer regularly. If there are any issues with suction, this could indicate a problem with the motor or other internal components, which may require professional repair. Check the vacuum pump: The vacuum pump is responsible for removing the air from the bag. If the vacuum pump is not working properly, the vacuum sealer will not be able to remove air from the bag, which will affect the seal. To check the vacuum pump, turn on the vacuum sealer and listen for any unusual noises. If you hear any unusual noises, you should have the vacuum pump checked by a professional. Store the vacuum sealer properly: When it is not used, store the vacuum sealer in a dry, cool place.

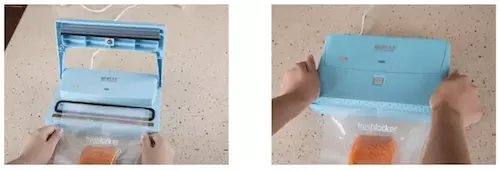

How to Use a Vacuum Sealer?

The process of using a vacuum sealer is relatively simple. First, you need to prepare your food by cleaning it and cutting it into the desired size. Then, place the food in a vacuum-sealed bag or container. Next, turn on the vacuum sealer and place the open end of the bag or container into the machine's sealing area. The machine will then remove all the air from the bag, creating a tight seal around your food. Once your food is sealed, you can store it in your refrigerator for extended periods without worrying about spoilage or freezer burn.

How Does a Vacuum Sealer Work?

The process of vacuum sealing involves placing food items in a plastic bag or container and then using a vacuum sealer to remove the air from the inside. The machine uses suction to draw out all the air, leaving only a tightly sealed package behind. The key to successful vacuum sealing is ensuring that there are no leaks or gaps in the packaging. This can be achieved by using high-quality bags or containers designed specifically for use with vacuum sealers.

What Kind of Food Should Not Be Vacuum-sealed?

Firstly, soft or delicate foods such as bread, cakes, and pastries should not be vacuum sealed as the pressure can cause them to lose their shape and texture. Similarly, fruits and vegetables with much water like lettuce or cucumbers can become mushy when vacuum sealed. Secondly, fermented foods like cheese or sauerkraut should not be vacuum sealed as they require air to continue fermenting. Vacuum sealing these foods can halt the fermentation process and affect their flavor. Lastly, raw mushrooms should not be vacuum sealed as they contain a gas called ethylene which can cause other vegetables in the package to spoil faster.

Shelf Life of Vacuum Sealed Food

The shelf life of vacuum-sealed food varies depending on the type of food and how it is stored. Vacuum-sealing removes oxygen from the packaging, which slows down the growth of bacteria and other microorganisms that cause spoilage. Dry foods such as grains, pasta, and beans can last up to two years when vacuum-sealed and stored in a cool, dry place. However, moisture-rich foods like fresh fruits and vegetables have a shorter shelf life of only a few weeks. Meat products can also be vacuum-sealed for extended shelf life. Beef, pork, and lamb can last up to six months when frozen after being vacuum-sealed. Poultry has a shorter shelf life of only three months. Dairy products like cheese and butter can also benefit from vacuum sealing. Cheese can last up to six months while butter can last up to nine months when properly sealed. Overall, vacuum sealing is an effective way to extend the shelf life of various foods but it’s important to note that proper storage conditions are crucial for maximum preservation.

Four Must Have Vacuum Sealing Accessories

Bags and Rolls

One of the most important accessories is a variety of bags and rolls. Vacuum sealer bags come in different sizes and shapes, so it's important to have a selection on hand to fit different types of food. Rolls are also useful because they allow you to create custom-sized bags for larger items.

Jar Sealer

One accessory that is a must-have for any household vacuum sealer is a jar sealer. This accessory allows you to seal mason jars and other containers, which is perfect for storing dry goods like pasta, rice, and cereal. It also helps keep your pantry organized and free from pests.

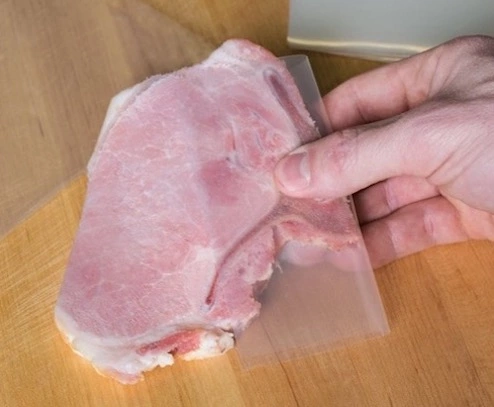

Bone Guards

Bone guards for household vacuum sealers are an essential accessory for those who frequently use their vacuum sealers to store meat. These guards are designed to prevent the sharp bones of meat from puncturing the vacuum-sealed bags, which can lead to air leaks and spoilage. The use of bone guards is particularly important when sealing larger cuts of meat, such as whole chickens or roasts. Without a bone guard, these cuts can easily pierce through the bag in the sealing process, compromising the integrity of the seal. In addition to preventing air leaks and spoilage, bone guards also help to ensure that your vacuum-sealed meats remain fresh and flavorful for a longer time. By keeping out excess air and moisture, these seals help to preserve the natural juices and flavors of your meats.

Vacuum Container

The vacuum container is a revolutionary invention that has transformed the way we store and preserve food. It is a container that uses vacuum technology to remove air from the container, creating an airtight seal that prevents spoilage and extends the shelf life of food. The concept of vacuum storage dates back to the early 1900s, but it wasn't until the 1960s that it became widely available for household use. Today, vacuum containers come in various shapes and sizes, from small containers for leftovers to large canisters for bulk storage. The benefits of using a vacuum container are numerous. Not only does it keep food fresh for longer periods, but it also helps to retain its flavor and nutritional value. Additionally, it reduces waste by allowing us to store food longer without having to throw it away due to spoilage.

How to Cook Vacuum Sealed Food?

Cooking vacuum-sealed food is simple and easy, requiring only a few steps. Firstly, preheat your oven or water bath to the desired temperature. Then, remove the vacuum-sealed bag from its packaging and place it in the oven or water bath. Ensure that the bag is fully submerged in water if using a water bath. Next, monitor the cooking time carefully as it may differ from traditional cooking methods due to the vacuum seal. Once cooked, remove the bag from the heat source and let it rest for a few minutes before opening. Finally, carefully open the bag and serve your perfectly cooked meal. Remember to discard any excess liquid that may have accumulated during cooking.

Can You Boil Food in Vacuum Sealed Bags?

Some experts caution against using plastic bags for boiling as they can release harmful chemicals when exposed to high temperatures. Instead, they recommend using BPA-free bags or silicone bags that are specifically designed for cooking. Boiling food in vacuum-sealed bags can be a safe and effective cooking method if done correctly. It is important to use appropriate materials and follow instructions carefully to ensure a delicious and healthy meal.

Can You Microwave Vacuum Sealed Bags?

Microwaving vacuum-sealed bags is a common question that many people have. The answer to this question is not straightforward as it depends on the type of bag and the food inside it. Generally, it is not recommended to microwave vacuum-sealed bags as they are not designed for this purpose. Vacuum-sealed bags are made of plastic and can melt or release harmful chemicals when exposed to high temperatures. Additionally, microwaving can cause the bag to explode due to the pressure build-up inside. However, some manufacturers produce microwave-safe vacuum-sealed bags that are designed for cooking in the microwave. These bags have special features such as venting holes or steam valves that allow air and moisture to escape during cooking. In conclusion, before microwaving any vacuum-sealed bag, it is essential to check if it is microwave-safe or not. If unsure, it is better to transfer the food into a microwave-safe container before heating. Safety should always be a top priority when using any kitchen appliance.